Empire’s Pre-Engineered Blast Booths (PEB) feature all the essentials for OSHA complaint blast rooms at a fraction of the cost. For many applications, requiring strict environmental and safety compliance, Empire’s PEB booths offer an attractive alternative to makeshift enclosures or higher priced custom blast rooms. After choosing your PEB size you can then choose from a list of standard booth options, dust collection systems, blast and recovery systems along with operator safety equipment. Because these systems are pre-engineered, they can ship in 6-8 weeks, almost half the time of a custom engineered system. See below for pictures and additional information.

Standard Blast Booth Enclosures (#14 Gauge Panels):

| 10’ wide x 10 ½’ long x 10’ high | 12’ wide x 10 ½’ long x 12’ high |

| 10’ wide x 14’ long x 10’ high | 12’ wide x 14’ long x 12’ high |

| 12’ wide x 17 ½’ long x 10’ high | 12’ wide x 17 ½’ long x 12’ high |

| 12’ wide x 24 1/2’ long x 10’ high | 12’ wide x 24 ½’ long x 12’ high |

| 12’ wide x 31 1/2’ long x 10’ high | 12’ wide x 31 ½’ long x 12’ high |

| 15’ wide x 14’ long x 10’ high | 15’ wide x 14’ long x 12’ high |

| 15’ wide x 17 ½’ long x 10’ high | 15’ wide x 17 ½’ long x 12’ high |

| 15’ wide x 24 1/2’ long x 10’ high | 15’ wide x 24 ½’ long x 12’ high |

| 15’ wide x 31 1/2’ long x 10’ high | 15’ wide x 31 ½’ long x 12’ high |

Unit of Measure

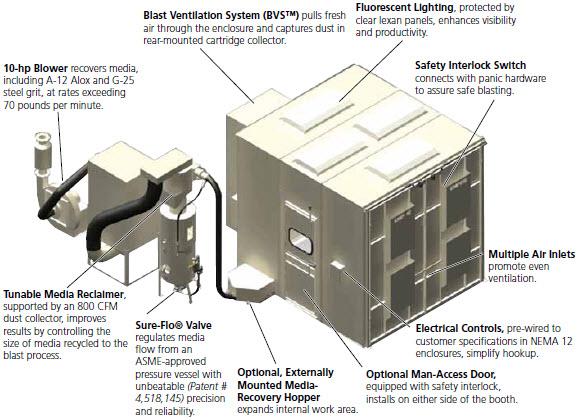

Features

|

Specifications

|

System Options

|

Operator Safety Equipment (Optional)

|

Warranty

|

Environmentally Safe

Specifications

|

|

|

Standard Blast Enclosures |

N/A

|

Pressure Vessel |

N/A

|

Blast Equipment |

N/A

|

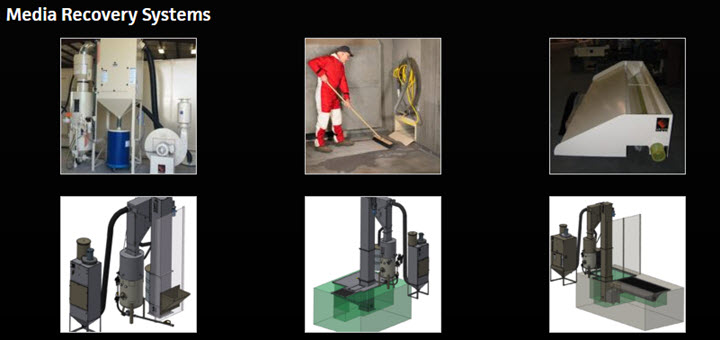

Media Reclaimer |

N/A

|

Pressure Blower for Media Recovery |

N/A

|

Dust Collector for Media Recovery |

N/A

|

Media Conveying Duct |

N/A

|

Media Recovery Hopper |

N/A

|

Media Storage Hopper |

N/A

|

BVS™ for Booth Ventilation |

N/A

|

System Options

System Options |

N/A

|

Operator Safety Equipment (Optional)

Operator Safety Equipment (Optional) |

N/A

|

Warranty

Warranty |

N/A

Empire Air-Blast Products

Information subject to change without notice. |

Environmentally Safe

Environmentally Safe |

N/A

Air-blasting eliminates many of the environmental problems and costs associated with chemical stripping because you don't have to manage or dispose of hazardous liquids. An Empire blast room provides even greater potential for improving safety and reducing operating costs when you're cleaning, finishing or surface-profiling large workpieces. With the process contained in a specially designed enclosure, blast media and debris are isolated from the external environment. And the operator, equipped with Empire safety gear, is fully protected. |